Hard Ties for Hauling

Your Bike

|

Zero Compression - Solid

Steel - Instant Attachment for a quick and easy haul!

|

|

Borrowing from the technology of the

Moki EZ Lock Tie Down Systems, I wanted

a similar, solid tie system for my trailer, which already has high end

LA Wheel Chocks and will not accommodate the Moki wheel chocks, which

are an integral component of their system package. If you are running

with a flat bed trailer, or other trailer that can handle the complete

Moki system, They come to your door ready to bolt in place, with no

modifications or calculated attachment points to worry with, but if for

some reason, like myself, you simply can't use the whole system, and

have the ability to modify parts, the non-chock system components are

all readily available and easily acquired, for a total cost of around

$150 per bike.

The Hard Tie System has some good points and bad points, so whether

it's right for you is purely a personal decision.

Pros:

Almost instant bike attachment to your trailer, with no adjustments

after initial setup.

Solid steel components won't wear out, won't break down over time,

and can't be cut by vandals. No need to replace every few years.

Zero compression of your bike's suspension means it's bike friendly

AND operator friendly!

Nothing touches your bike but two permanently mounted chrome frame

clamps. No paint or chrome marring, no padding the bike parts!

Fail Safe! Even if one side has a complete failure, the other will

prevent the bike from falling off the trailer, and if coupled with a

clamping type wheel chock, it will continue to hold the bike upright and

in position. No need for backup ties or safety straps.

LOCKABLE! By utilizing padlocks in place of linch pins, you can

lock your bike to the trailer! (This could be defeated by a crook with

lots of time on his hands, by twisting the bars four million times until

the ends fall out).

Cons:

Expensive! Compared to common tie down straps, the Hard Tie system

is about three times the cost per bike of ties and straps.

Permanently attached hardware on the bike. While this is a "pro"

for convenience, it is a "con" for aesthetics.

(Makes for good conversation though at bike-nite meets! ;-)

Not "Universal". Because of the installation of bike specific frame

clamps, this system does not lend itself to hauling other non-fitted

bikes. Rescuing or hauling a friend's bike would still require the use

of tie straps, so don't throw out your old straps and hook anchors!

Having your bike solidly connected to the trailer means your bike

may be subject to more vibrations, depending on the suspension qualities

of the trailer. Strap ties do allow more of a buffer between the bike

and trailer because there is no metal to metal contact between the two.

Similar systems have been used for years by many people, but if this

ever proves to be a problem for me, rest assured that I will make that

known on this page!

WARNING!

Your bike trailer MUST HAVE adequate leaf

spring or torsion bar SUSPENSION to accommodate a hard tie

system without issues. My Baxley Trailer has NO SUSPENSION other than

two thick rubber pads that the axels rest on, therefore, with much

regret, after four years and over 6000 thousand miles of transport, I am

removing my hard tie system from this trailer, as I have experienced

five broken eyebolts over this period due to rough road conditions and

lack of pothole absorbing wheel travel on the trailer. Each time an

eyebolt popped, the second bar held the bike securely, and I didn't

notice the broken part until I reached my destination, but I have come

to the conclusion that THIS trailer is simply not suitable for the hard

tie system, but I love the trailer more than I do the hard ties, so I've

gone back to the traditional tie down systems.

Sources: Except for the

KuryAkyn Magnum Frame Clamps, all the

necessary (3 point hitch) components are available directly from

Tractor Supply Company,

and your local hardware store.

Tools: Drill with 1/2" Bit, Adjustable Wrench, 3/4" Wrench,

Dremel Tool with Tungsten Carbide Cutting Bit, Centering bar or other

similar rod.

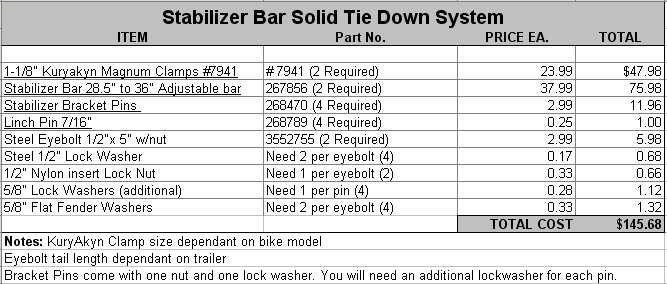

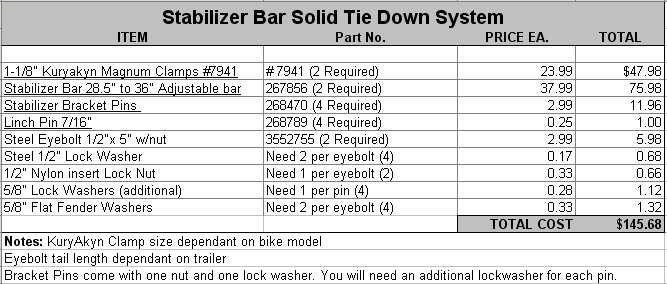

Hardware: All prices shown on this page are per the time of

this writing (2011), and subject to change without page updates!

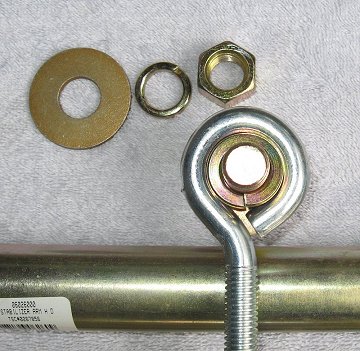

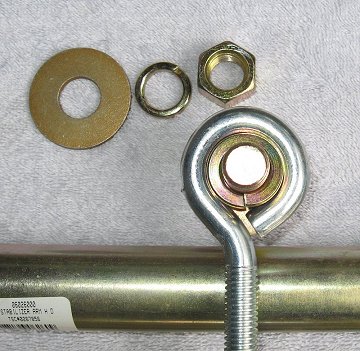

To create "base pin" assemblies for the trailer,

simply bolt a bracket pin through an eyebolt, using two fender

washers on either side, a lock washer on the nut side, and an

extra lock washer in the center of the eyebolt. This extra lock

washer will compress into the center of the eyebolt and serve as

a centering spacer to prevent the bracket pin from shifting in

the larger eyebolt hole. (note: you might find it easier to fit

the extra washer in the eyebolt if you snip off a 1/8" piece

with some bolt cutters or Dremel cutoff wheel.)

Use a one inch wrench, socket, or adjustable wrench

on the pin nut and a centering bar or other long bar inserted

through the linch pin hole to hold the pin while tightening down

the nut.

|

|

By far, the

hardest part of this whole project is increasing the hole size

in the KuryAkyn Magnum Clamps to accommodate the 5/8" thickness

of the bracket pins. Those Kury clamps are HARD STAINLESS STEEL!!

I found it useless to try to drill the holes out

larger, and ruined a $15 5/8" bit within minutes on the first

attempt. I found that a Dremel Tool with a Tungsten Carbide

reaming bit would cut the hard metal without a lot of effort,

but prepare for some "whittling" time. It takes about 15-20 minutes

per hole to slowly ream them out to size.

Tip: Wear gloves, protect your eyes and skin,

and work outdoors. Those reaming bits throw out millions of tiny

slivers of sharp edged steel which can become instant splinters!

I put a fan beside me to help keep the steel splinters blown

away from me and off my clothing.

|

|

|

Sub-Assemblies are now complete, and we're

ready to move out to the bike and trailer!

|

You will need

to set the bike up on the trailer to determine exact locations

for the base pins on the trailer and the Kury clamps on the

bike. If you're not using a clamping wheel chock, have someone

sit on the bike and hold it upright or lightly secure it upright

with tie straps.

Base pins assemblies should be located at a strong frame member

on the trailer. Lightweight flooring material will not support

the system.

|

|

|

The base and bike pins should be oriented

parallel so the tie bar can easily slip off one side and in one

direction. This can be inside toward the fender or outside away

from the bike. Just make sure you have adequate fender clearance

to the pins, nuts, or brackets with the bike fully compressed or

you'll be mad at me later!!

Additional large fender washers should be used

on the base assembly eyebolts if mounting to a wood floor.

|

|

|

Although my bike pins are a little more

noticeable oriented to the outside, I prefer working the bar

outward, away from the fender. This is an easier attachment and

less vulnerable to accidental paint damage.

Note: For better clearance between the bar and

the Magnum clamp, use a 5/8" lock washer on BOTH sides of

the clamp. This spaces the pin out just a tad so the bar doesn't

ride against the chrome bracket surface.

|

|

|

Two bikes, strapless and ready to roll!!

To finish off this project, I painted the

small parts with satin black engine paint and baked them for a

bit at 350 degrees, then I ordered

some

1.5" PVC heat shrink protective tubing for the stabilizer bars.

This thick PVC covering will help protect them from

banging against other metal parts of the trailer and bikes, give

them some extra weather protection,

and tone them down to all black. (The Road King set in the

photos above is

temporarily covered with carbon fiber wrap.) and finally I added

some 1 -3/16" rubber pipe seal rings just to keep them from

laying flat on the metal floor of the trailer.

|

Gallery

|