|

Seems like somebody forgot their thinking cap when

they let all the electrical goodies fire up before the

engine does (or maybe they just want to sell more

batteries). Suzy's seem to be a bit finicky with regard

to the amount of available juice to fire off a cold

engine. Couple that with the fact that batteries are at

less than optimum output when they are cold, and you got

the potential for a non-ride event.

Not to brag on the brains of a competitor, but Kawasaki

Vulcan does not let its lights come on until after the

starter button is released. Now on a scale for things

that make sense, I'd rank that one right at the top,

alongside the Valkarie's brake reservoir windows facing

the rider!!

Soooo...my big winter project for 2000 was to incorporate

a pull type brake light switch and relay(s) into the

kickstand mount which would control the lights, so that

when the stand is down, no juice will go to the headlight.

JC Whitney Relay Switch Pt# 14JE9433Y ($5.95) (get two

if you want to cut the tail & running lights)

Dennis Kirk Part no. 21-0119 Universal Brake Light Switch

$5.99.

(or Chrome Specialties Brake Light Switch, part no. 37054

available from your local Harley shop.)

Corrugated flexible electrical tubing (from AutoZone) $2.95

Bullet electrical connectors (from AutoZone) $1.79

Primary wire (already had that)

Total investment: Approximately $30.00 ($10 of which was

shipping costs)

Estimated return on investment: We won't even go there ;-)

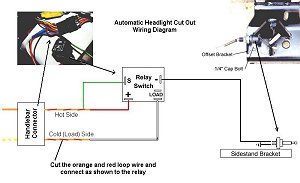

The Black and Green wires are the "Working"

wires to the relay. Load the green one and ground the

black one (or vice versa) and the relay will click into

action. The Red, Yellow and White wires coming from the

relay are the "Duty" wires.

The Red wire is the primary load wire. It should be wired

hot.

The White wire goes hot when the relay is grounded (circuit

is closed).

The Yellow wire goes hot when the relay is not grounded (open

circuit).

Remove the Yellow wire from the relay plug, you won't be

needing it.

WHERE TO

INSTALL THE RELAYS:

|

Inside the headlight housing, you

will see two loop wires on the connector that

comes down from the right handlebar control.

These two loops are the lifelines to the

headlight, and the tail/running lights, and this

is the magic spot for the relay(s). (Using the

kickstand switch as a relay ground, you can

control two relays with the one switch, and cut

the tail/running lights as well as the headlight)

At the headlight/handlebar junction plug, cut the

Orange w/Red loop wire that connects the Orange

to the Yellow/White wire.

Connect the Orange side of the wire (the hot side)

to the Green and the Red wires that go into the

relay switch.

Connect the White wire from the relay to the

Yellow/White side of the loop wire (the cold side).

Run the Black wire (inside the corrugated conduit)

from the relay down the frame and under the

engine case on the left side, and run it all the

way back to the driveshaft.

If you wish to cut the tail/marker/speedo lights

and horn as well, wire a second relay into the

remaining loop on the plug in the same manner.

However, you will not need to run the black wire

to the Kickstand, you can just splice it into the

one from the other relay. |

Relay

Click the image for larger format

|

|

Click for larger format |

The relay that I used came with its

own connector and pigtail wires, therefore the colors of those

wires were described on this page and depicted in the diagram

above. If you purchase a relay with no wiring attached, you may

use any color wiring you wish as substitutes for what I have

shown.

To find the hot and cold sides of the loop wire, look at the

backside of the connector for the solid orange, and the yellow

and white stripped wires. The orange is hot with the ignition,

so the half of the loop directly on the other side of the

connector is your hot half.

|

THE FUN

PART: (THE SWITCH)

|

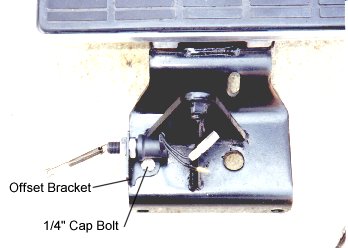

The pull switch will be mounted

to the inboard topside of the heavy steel plate

that supports the left driver footboard and

gearshift lever. Then it will be connected to the

kickstand by using a small nickel plated chain (hardware

store item). This chain will be used instead of

the usual spring wire, due to the length of

travel of the kickstand. This will allow you to

set the switch in the "on" position

with the kickstand up, then the chain simply sags

down when the stand is down, allowing the switch

to close.

The pull switch will be mounted to the plate via

an offset corner bracket. (See mounted switch

photo.) You can simply drill a 1/4" hole

through the plate and bolt the bracket down.

Connect one switch wire to the Black wire from

the relay switch(es), and connect the other one

to a short section of wire, and ground it

somewhere nearby. |

Bracket

|

Drill a small hole into the solid part

of the kickstand just down from where it becomes a "U"

(This can be done without removing the kickstand). Secure

the chain to the kickstand by threading a cotter pin onto

a link in the chain, then through the hole you just

drilled. (Be sure to locate the hole and the cotter pin

so that it doesn't interfere with the operation of the

stand). Check to make sure that the chain does not pull

the plunger out to it's limit when the stand is up, then

snip off any excess chain. NOTE* The chain can

also be attached via a small cable tie if you prefer not

to drill into your stand.

Now, when the stand is down the circuit to the relay is

ungrounded, and the headlight/tail/running lights will

remain off. Lift the stand and on come the lights!!

| Switch Off

|

Switch On

|

Relays are hidden in the headlight housing. Switch

mechanism is neatly tucked under the floorboard, and

everything works automatically. Now the battery can

concentrate on the important stuff, like cranking a cold

engine, and recuperating during warm-up!!

A piece of heavy copper wire, or gem clip can be bent

to hold a loop in the chain, should you have a need to

park the bike with the lights on (Emergency or roadside

assistance, etc.)

In the event of any electrical component failure, all

connections were made with opposing bullet connectors,

which will allow instant "bypassing" of any

component used in this setup.

Optional

Setups for those less technically motivated

|

Although I prefer the more controllable configuration

above, many people do not feel that they need this much

control, or want to get this complex.

As a less expensive, less technical, and certainly less

effective alternative, a single relay can be wired from

the Yellow/Green Starter button wire to kill the light

just when the starter is engaged. Wire the relay to be

"Normally On", then use the starter tap wire to

cut the relay Off while the starter is engaged. While

this does nothing to reduce the ignition switch draw

down, nor does it aid in after-start recovery, it is

easier to install, and with virtually no concerns over

component failure.

|