|

Pair Valve (2nd Air)

System Removal - The Final Chapter!

Removing the Electronic

Solenoid from the Harness

For those who wish to

shed the entire system on their FI equipped C90, C50,

M50 models

THIS IS A DIY PROJECT AND REQUIRES

THE ABILITY TO SPLICE AND SOLDER WIRING

|

|

For the Boulevard Cruisers with Fuel Injection

systems, when you remove the pair valve (also known as "2nd Air" System)

from the bike, it is usually necessary to leave the small film canister

sized electronic solenoid attached to the bike's wiring harness in order

to avoid getting a fault reading during routine startup diagnostics

(engine light on). The reason for this is that the system will send a

signal to the solenoid to make sure it's there and working, and if it

isn't, you'll be notified with the check engine light. This last little

nagging part can be dealt with by replacing the solenoid with an inline

resistor, which will satisfy the diagnostics check.

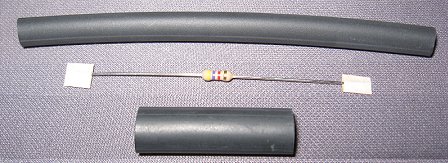

This is a complete pair valve

assembly, with solenoid still attached. Your bike's assembly may

look slightly different due to model variations, but the

solenoid (wired) part is essentially the same on all C90, C50,

and M50 bikes.

|

|

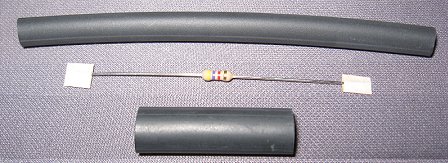

This is the solenoid after having been removed

from the pair valve assembly. Below it is a 4.7k-Ohm 1/4 Watt

inline resistor that we'll use to replace the solenoid on the

wiring harness.

These resistors are available from most any

electronics store, or you can order them in bulk through

Amazon

|

|

It will be necessary to cut the original pigtail

wire from the solenoid in order to solder in the resistor and

have a plug-n-play component. Although the solenoid COULD be put

back into service by splicing the original wires back together,

this should be considered a permanent change to the bike.

NOTICE!

That solenoid is a $180 part, so if you think there's ever

a chance you might want to put it back to original

configuration, STOP NOW and just plug the solenoid back into the

bike harness as per your pair removal instructions!

|

|

Please note: If at ANY TIME during the removal process, you

purposely or accidentally turn your ignition on, while that

connector is not in place, your bike will record a fault in the

system, and may continue to light the check engine light for up

to 50 start ups. To avoid this annoyance, remove the key from

the ignition before you ever start your project!

|

|

|

Many thanks to my cyber

friend Daniel "Redfire 05GT" from the Volusia Riders for

technical and component information for this project!

|

|