Time for new rubber?

|

Save some chrome and

cruise money by doing some or all of the work yourself!

|

|

If you bought your bike to ride, and are getting your money's worth,

chances are, you're going to get on a first name basis with your local

shop guy just for tire changes! If you're already doing some of your own

maintenance, and want to save some stress on your budget, why not

do some of the labor yourself, and save the hassle of having to drop the

bike off or make an appointment and sit. (If you're sitting, you're

paying dearly for the privilege of sitting!)

With a jack and a few simple tools, you can significantly reduce your

tire change costs by removing your own wheels. Not only will this save a

pile of labor costs, but it will open the door for you to shop at other

non-Harley places for better tire prices. Any shop that owns a tire

changer can change your tires if you bring in the wheels, but they may

not have mechanics trained to work on your BIKE if you ride it in.

This is a start-to-finish tire change site, including removal and

replacement of both wheels, and for those who want to save more, we'll

show you what you need and how to change the rubber out as well,

enabling you to take advantage of great web and catalog sales on tires!

REAR WHEEL

Click images for Larger Format |

You'll save a lot of time if you already know what

tools you need for the job, so let's start with the basic list:

Service Jack / Torque Wrench / Ratchet / 36mm

Socket / 3/4" Socket / Bungee Cord / Large Adjustable Wrench (or

36mm Wrench) / Rubber Mallet / Tapered Pry Bar / Anti-Seize

Lubricant / Beverage of your choice / iPod full of Rock & Roll

Classics

Optional Muffler removal tools: 9/16" Socket / 1/2"

Socket / Rubber Strap Wrench (helpful but not absolutely

necessary)

|

|

| Belt tension

rarely changes after the first few thousand miles. If you do

not need to change the tension on your belt, you can pull and

replace the rear wheel without removing the mufflers, and we'll

show you how to mark the axel for undisturbed belt tension. The

photos below are of a 2002 FLHR. Wheel removal is almost the

same on all touring models. |

After removing

the saddlebags, and supporting the bike's weight by the service

jack, grab your 3/4" socket and ratchet and loosen the

top shock bolts, then remove the bottom shock bolts,

then use a bungee cord across the rear fender to hold both

shocks back out of your way. This method is used to avoid

removal of the mufflers. You can remove the mufflers for more

access, or if you need to adjust the belt, but muffler removal

can be frustrating, and will eventually require new Torca clamps

as well.

I don't pull my mufflers unless I need to. Saves

time, money and cuss words. :-)

|

|

|

Lower the service jack so that the rear tire rises to a

point where the axel nut is slightly above the saddlebag support

rail |

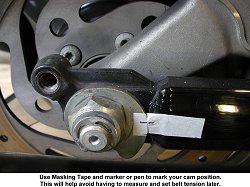

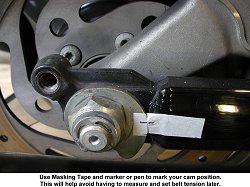

On 2002 and

later models, lay a strip of masking tape across the

axel cam and swingarm, then mark an index line on the tape where

it bridges over, and finally, slice the tape at the edge of the

cam plate. Do the same thing on the opposite side.

This is your belt tension mark, and will ensure

that your belt tension remains unchanged after the tire change.

Earlier models use a pair of adjustable axel

yokes at the back of the swingarm. Mark the top of the yoke

bolts with a marker, then count and record the number of

loosening turns you make to free up the belt, and turn BOTH

bolts exactly the same number of turns. On reassembly, tighten

both bolts equally the number of recorded turns.

|

|

Remove the

axel nut retaining clip (see previous photo), use your

36mm socket to remove the Axel cone nut, (100lbs torque, be

careful and make sure your bike is secure on the jack!) and the

right side cam plate.

Now, making sure that the axel and cam plate on

the left side will clear the saddlebag rail, push or tap the

axel out with your pry-bar or similar rod. If you have a tapered

pry bar like the one in the tools photo, it's point will

rest in the dimple on the end of the axel. Tap the pry bar

through with a rubber mallet if it is stuck.

|

|

| With the axel removed, roll

the wheel forward to allow the belt to be released off the

outside of the pulley. The brake caliper support will slide

forward as the wheel is moved.

The swingarm will now drop down and the short right spacer

and long left spacer may drop out onto the floor, so keep an eye

out for them. |

|

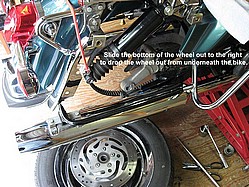

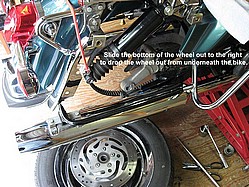

| Now ease the service jack up

as you work the wheel free from the brake caliper, leaving the

caliper in place on it's sliding tab. Once you get some height

on the bike, you can pull the bottom of the wheel to the right

and slide the wheel out from underneath the bike. |

|

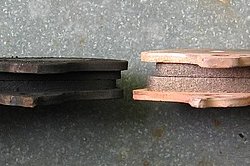

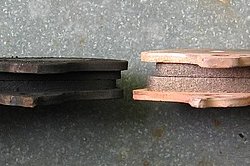

| Now is a REALLY good time to

inspect your rear brake pads!! They are much easier to replace

with the rear wheel off.

My rear pads were ok, but I'll be making several vacation

weeks in the mountains before this tire is gone and I don't want

to be concerned with the rear pads going before the tire does so

these are getting replaced with a new set for safety and

convenience.

Harley Part number for replacement pads for '00 to '07 models

is 44082-00D |

|

| Whether you

choose to replace your brake pads or not, spray the inside

caliper area around the pistons (between the pads and caliper)

liberally with brake parts cleaner spray to help remove dirt and

grime from the pistons and keep your brakes working smoothly. |

| Reassembly after the

tire is changed is simply reversal of the instructions above.

After pushing the wheel forward to loop the belt over the

pulley, Use the pry bar, to loosely assemble the wheel, spacers,

brake caliper support and swingarm. If the axel hasn't

previously been coated with anti-seize lubricant, clean off the

corrosion as best you can and wipe the whole axel down with the

lubricant. Then work the axel through from the left side,

pushing the pry bar out as you go. This part is a little

frustrating, but take your time, wiggle the parts, and it will

go. (this is where the iPod comes in handy! ;-) |

|

| Roll the axel forward by

twisting the welded nut on the left side, to set the cams at

some point looser than original, then push both sides of the

wheel forward to get good contact between the cams and the weld

nub on the swingarm. Tighten the axel to 15 ft-lb. of torque,

then slowly rotate the left nut until your belt tension

alignment marks line up. Now torque the axel nut to 100

ft-lbs.

On pre-2002 models, evenly tighten the axel yoke bolts the

same number of turns you initially loosened them. |

|

| Reinstall the shock lower

bolts and tighten both lower and upper bolts (35 ft-lbs).

Depress the brake pedal a couple of times to reset the brake

pads, and now's a great time to check and set your rear shock

pressure too! |

|

| Take an easy test

ride and allow rainy-day braking distance until you are

confident that your tires are scuffed in and your brake pads are

properly seated.

|

Now, click here to follow me and we'll do the front wheel.

Or click here and we'll move over to the tire changer.

And here's a printable quick list of tools and torque values for you.

Tire Change

Tools PDF

|